Electrical Systems Installation & Wiring

CoE with large EWIS talent pool of 100+ Electrical engineers

Multi-program experience – Business jets, defence and commercial aircrafts

End to End responsibility: System Schematic Design > Harness Installation | Nose > Tail

of the aircraft

Value Addition

Efficiency

90%turn around time increase

Expertise

350+Alternative design solution

Sustainability

4 Yrsturn around time increase

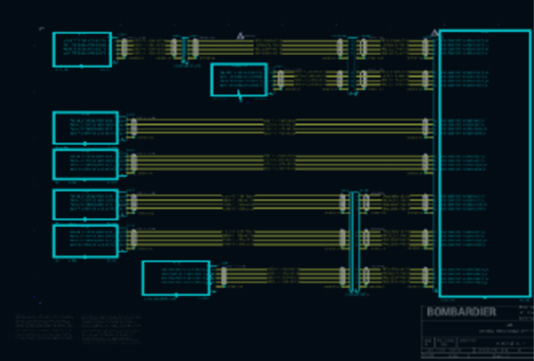

2D Design

System Schematic Design

Wiring Diagram Creation

Topology/Roadmap

Harness Layout Design

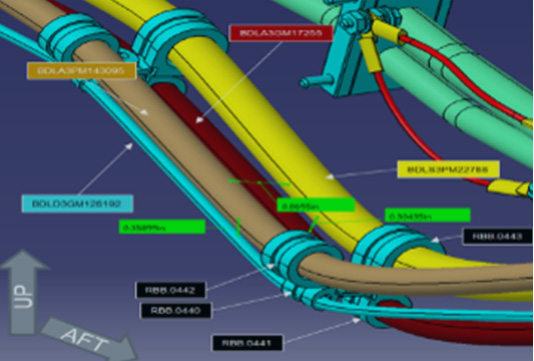

3D Design

3D Harness Routing Design

Secondary Brackets Design

Library Parts Creation

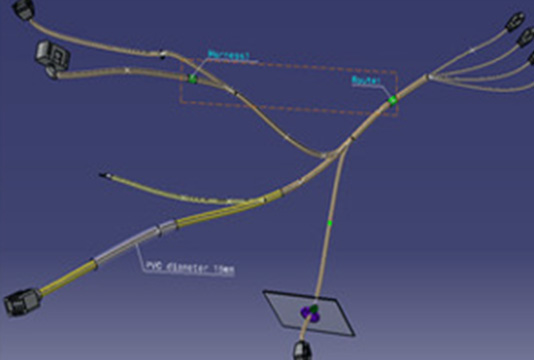

2D-3D Bridging

2D-3D Integration

Harness Stick Diagram

Harness Report Creation

Manufacturing Engineering

Electrical Methods

Installation Drawings

Assembly Manual Preparation

Formboard Drawings